A site dedicated to discussion of these classic boats

22 Feb, 2015 1 Comment

Filed in: servicing, storage, winterizing

I haven’t had much opportunity to post in recent months–let alone do any work on the boat. Seatoad sits in the driveway under a mantle of snow and ice. this winter has been particularly harsh–over eight feet of snow in Boston and still a month to go until spring. A few weeks after Christmas I pulled off the cover long enough to lay a bunch of planks across the gunnels. Good thing or the snow would have collapsed the cover long ago.

I haven’t had much opportunity to post in recent months–let alone do any work on the boat. Seatoad sits in the driveway under a mantle of snow and ice. this winter has been particularly harsh–over eight feet of snow in Boston and still a month to go until spring. A few weeks after Christmas I pulled off the cover long enough to lay a bunch of planks across the gunnels. Good thing or the snow would have collapsed the cover long ago.

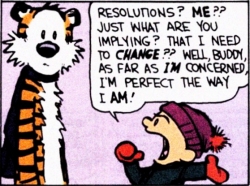

This afternoon I finally got around to starting a preliminary spring to-do list for the boat. There’s a lot that needs doing.

The rest of the items are related–one way or another–to the repower I did last spring. While the new engine itself is great (a Honda 4 stroke) the work done by the service center was awful–sloppy and rushed despite taking six week. They even broke a few things on the boat in the process.

what I need to fix:

16 Jan, 2012 No Comments

Filed in: football, legal, servicing, storage, winterizing

The whole month of December without a single post! After a busy boating season I needed a little down time. But it’s time to get busy again. Been working on some bugs/enhancements to the gallery/upload pages and got most of it figured out yesterday while watching the NFL divisional round games (the Giants look like they’re peaking at just the right time…they’re going to be very tough).

The whole month of December without a single post! After a busy boating season I needed a little down time. But it’s time to get busy again. Been working on some bugs/enhancements to the gallery/upload pages and got most of it figured out yesterday while watching the NFL divisional round games (the Giants look like they’re peaking at just the right time…they’re going to be very tough).

Finally (finally!) in the first week of January got the boat tarp/cover fixed on in such a way that it won’t blow off in a high wind or cave in and pull loose after a heavy rain/snowfall. Up to this point I had the tarp tied with sash cord. But a good rain would load the top of the cover with water causing it to belly down into to boat. This in turn would stretch and loosen the sash cord, and then the next really wind day would just lift the whole thing off. I solved the bellying issue by cutting a bunch of wooden slats to the width of the boat and then laying them atop the gunnels (plywood would have worked too but I figured that’d be heavier and more awkward to put on and off). I solved the loosening problem by doing what you’re supposed to do…affixing the cover with heavy duty bungee cords.

The battery is still in the boat, instead of down in the basement on a trickle charger like it should be. I wanted the option of still being able to raise and lower the motor. But now that we’re into the truly frigid months here in Massachusetts it’s time to put it where it belongs.

Tasks for the month:

Shopping lists for boat/trailer parts and fishing equipment will have to wait until February.

findre August 9, 2015

findre August 9, 2015

findre August 9, 2015

Lcolon7 June 23, 2015

MikeQ June 24, 2015