A site dedicated to discussion of these classic boats

1 Apr, 2012

Filed in: bilge, plumbing, reference

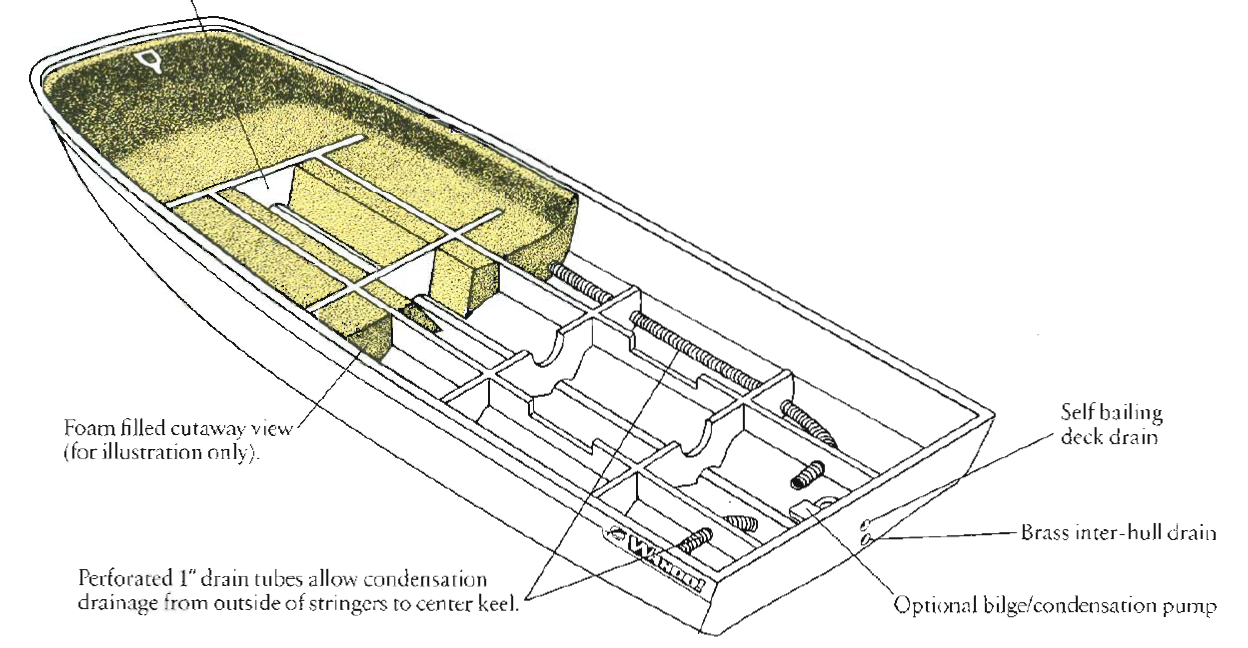

As a companion piece to the post on the Wahoo!s above-deck drain system, here’s one on the Wahoo!’s below-deck plumbing. Like the self-bailing deck, the Wahoo! hull interior is one of the most confusing features of these boats. As with the post on the deck drain system, I’ll update this article if and when new info becomes available. Note also that this post deals specifically with smaller Wahoo!s–the tri-hull models. For all I know the larger Wahoo!s (say, those over 21 feet) and/or the V hulls had a very different design. So your mileage may vary.

Basic to understanding the design of a Wahoo! is knowing what’s going on insider the hull. Some key points:

Wahoo! hulls contain foam. This helps with buoyancy of course. Boston Whaler hulls are foam “filled.” The “filled” part means every bit of the hull interior is filled with sprayed-in foam. This not only maximizes buoyancy, it also in theory keeps water out of the hull because there’s no literally place for it to collect. But there are a few potential drawbacks to this design. For one, because there is the assumption of no water ever entering the hull, Whaler hulls do not have a drain plug. That means if somehow water DOES manage to get in there, there’s no easy way to get it out. A second concern is that over time the hull foam may begin to absorb water, not unlike a sponge. The water could come from the outside or it could come from condensation inside the hull. Either way, as the foam absorbs water it takes on weight. That causes handling problems. And over time the moisture can cause the foam to break down.

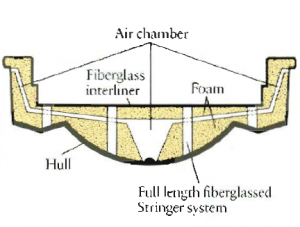

Distinct from Whalers, Wahoo! hulls are foam “lined.” The “lined” part means that the top, sides, and bottom of the hull interior are coated with blown-in foam but there is an air cavity in between. Also the Wahoo! hull includes a drain hole in the stern. The advantage of this design is that the cavity allows the interior foam and stringers to “breathe”; that is, the ability to dry. And any water that does get into the hull can be drained. The downside, compared to the Whaler design, is that with less foam comes less buoyancy, and the air cavity allows water a place to collect.

Cutaway showing Wahoo! foam liner and air cavity. Cutaway showing Wahoo! foam liner and air cavity. |

The original Wahoo!s from the mid 80s design did not include a bilge pump. Since that time 25 years’ worth of Wahoo! owners have wondered why, because water certainly finds its way into Wahoo! bilges, as it does with any other boat. It’s not immediately clear what the the absence of a pump meant from the manufacturer’s perspective. Maybe it meant the company had a misplaced faith that water wouldn’t get into the bilge. Or maybe it meant they assumed that most Wahoo!s would be used as trailer boats whose drain plugs would be opened after every use. Or maybe it was simply an attempt by the company to cut costs and leave it to customers to add their own bilge pumps. Whatever was behind the initial decision to omit a pump, it was not adequate. Within a several years Wahoo! brochures began mentioning an “optional” bilge pump.

So does your Wahoo! need a pump in the bilge? First, let’s talk about the ways that water can get into the bilge. Leaving aside leaks in the hull exterior (but all the more reason for a bilge pump), you have:

These things together or alone can allow quite a bit of water into you hull. Water is especially good at finding its way in when its got some force behind it, such as wind-driven rain or when you’re hosing the deck. Given the relatively small size and weight capacity of Wahoo!s, and that a gallon of water weighs seven pounds, it doesn’t take much to affect performance.

So to the question of whether your Wahoo! needs a pump in the bilge, I say the answer is, yes, absolutely. Even if you keep your boat on a trailer, the added safety and security that a bilge pump gives you make it well worth it. The installation is easy and inexpensive. I would not waste time considering a manual pump–put in an electric one and be done with it.

Locate the pump in the spot shown in the diagram above, at the rear of the bilge along the keel. This is the lowest section of the hull and where all water will run to. Most Wahoo! tri-hulls come with a five inch access port in the center of the stern through which you can install the pump. If yours does not include an access port you’ll need to add one.

Here are a few notes on the pump I installed in case it’s helpful to anyone. There are certainly other ways to do it.

Rule 360 bilge pump. Rule 360 bilge pump. |

Hose from bilge pump exists through hole in access port cover and drains into splashwell.. Hose from bilge pump exists through hole in access port cover and drains into splashwell.. |

Just as I was finishing this post I wondered whether anyone had ever configured his Wahoo! so that a single pump handled both the above and below deck drainage. You could achieve this pretty simply by installing a pump in the bilge and then drilling about a one inch hole in the bottom of the deck sump basin. That would dump all water that enteredd the boat into the bilge. It seems like a bad idea for a few different reasons, but man if anyone has ever tried it I’d love to hear how it went.

Here’s a little more reading on the subject:

http://www.thehulltruth.com/boating-forum/96775-16-wahoo-water-hull.html

(Note: in this message thread Monstawhala states that the top hole in the deck sump basin drains into the bilge, and that both stern compartments also drain directly into the bilge. That is not correct. The stern compartments drain into the sump basin via the aforementioned top hole in the sump basin.)

You must be logged in to post a comment.

I was thinking the same thing,about drilling a hole about one inch in the deck sump so thw water can drain into the bilge intern pumped out by bilge pump.What do you think?

Hi Ray. I wouldn’t do it. For one thing, suppose the pump in the bilge fails (which they do, of course)? then you’ve got the potential for a lot of water below deck and no easy way to get it out. In a boat as small as a Wahoo!, as little as ten gallons of water in the bilge can noticeably affect handling. I think the goal should be to try to keep water from getting into the bilge in the first place. Then use a pump to deal with what gets in there anyway.

Hi Mike, i am trying to figure out the bilge pump situation and am a bit confused by your description. I have an 87 16.2 and it seems like if i pump the water into my splashwell while the boat is at rest the water will drain back back into the boat. Am i missing something?

Hi jq. The splashwell is the drainage area immediately forward of your transom. It’s walled off from the rest of the boat interior and has two drain holes. The drain holes are located above the water line and pass through the transom to the outside of the boat. So any water dumped into the splashwell simply drains out the stern of the boat.

Thanks Mike, i’m new to boating and soaking up what i can thru, books, conversations and forums. The 87 1650 wahoo i just bought has a 99 4 stroke 70 and i think it’s too much weight for the boat. The 2 drainholes inmy splashwell sit below the waterline. I just relocated the battery from the rear storage space to under the center console to pull some weight forward and that helped a bit

My splashwell drain holes sit right about at the waterline, or maybe an inch above. It’s common and fine for the bottom of your splashwell to be “wet” most of the time when the boat is at rest.

My 16.2 Striper’s current engine is a 3-cylinder with power tilt that weighs in at about 250 pounds. It could probably handle a little more weight in the engine although I’d rather not go that way. But I confess I’m not an expert here or that I know how to determine how much weight engine-wise a boat can handle. People do have a tendency to overpower their boats but appropriate HP is a different issue from appropriate weight.

If you’re concerned about engine weight I guess I’d start by asking how much freeboard do you have in the stern and do you have trouble getting your engine up on a plane? The 16.2/1650s have a relatively low weight capacity, so the heavier your engine the less capacity you have for other things.

My drains are about 2″ below the waterline and i have about 4″ of freeboard. It would only plane out at high speed so i added a hydrofoil and that helped quite a bit. I think there is too much weight in the engine for my situation but unfortunately that didnt occur to me when i was buying the boat.